YCM UV 650 High Performance 5-axis Vertical Machining Center

The YCM UV 650 5-axis vertical machining center provides excellent cutting performance and high accuracy. Designed to reduce part handling, setup and overall lead-time, while improving part quality, precision and surface finish of complex shapes and contours required for multiple industries such as job shop, medical, aerospace, and die & mold.

Features of YCM UV 650

- 12,000 (15,000) rpm IDD PLUS spindle

- ø650 mm ø25.6" 2-axis B/C type tilt-rotary

- Max. workpiece weight 300 kg 661 lb

- ATC magazine: 40T(std.) 48 / 60T(opt.)

- X/Y/Z-axis rapid rate 36 / 36 / 36 m/min.

- Compact footprint

- User-friendly machine designed for easy operation

YCM In-house IDD Spindle

- The YCM IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

- Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

- Powerful 17 kW max. hollow shaft spindle motor – allows machining of the toughest materials, while also providing with fine surface finishes and the ability to add CTS 70 bar (1,000 psi) coolant through spindle (CTS) easily.

Robust Structure Design

- High Quality, Rugged MEEHANITE™ Castings – YCM's In-House Foundry follows strict international MEEHANITE standards ensuring high stiffness, rigidity, and vibration dampening that results in superior thermal stability, and cutting performance.

- Reinforced saddle features provides optimum stiffness, rigidity and stability.

- Extra wide base and column design enables solid support and excellent cutting performance when machining complex parts at a high feeds and speeds.

Accurate and Thermally

- Linear scales are mounted in X/Y/Z-axis and rotary encoders in the B & C axis allowing for the most demanding machining accuracies.

- The X/Y/Z-axis are fitted with high precision roller guideways and fixed pre-tensioned, double-nut, direct drive ballscrews, allowing for fast and accurate machining.

B/C-axis Rotary Table

- High precision rotary encoders in the B and C axes as a standard feature, allowing for the most demanding machining accuracies.

- Larger size tailstock support allows fast, rigid and accurate machining of complex 5-axis components.

- The tilt-rotary table features a full circular hydraulic braking system that provides rigid B/C-axis clamping during indexing machining applications.

Tool Magazine

- Chain type 40T magazine as standard.

- Wide selection of optional tool magazine, including 48 / 60T.

- Absolute encoder ATC system tracks tool pot position in the event of a mishap.

Automatic Tool Changer

- Tool to Tool time: 1.8 sec.

- Standard ATC auto door minimizes chips and coolant from entering the tool magazine area.

- This design incorporates an inverter type cam-box-motor for easy ATC recovery in the event of a mishap. The tool change arm is designed for low inertia allowing precise positioning and long service life.

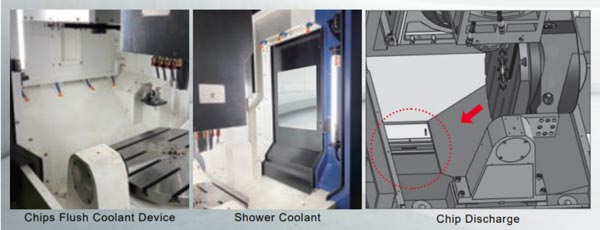

Chip Removal

- 4-coolant lock lines around the spindle, 2-coolant lock lines on the right side of the spindle, cutting air-blast with 1-lock line on the right side of spindle, coolant gun, and air gun.

- Standard shower coolant nozzles mounted from the roof provide optimal chip removal.

- Efficient chip discharge with steep angle allow unhindered chip flow to the chip conveyor.

User-friendly Operation

1. Large front and right side doors allowing easy reach and unrestricted access.

2. Optional right side automatic door can be selected to combine with robot, gantry, or pallet allowing for automated unmanned operation.

3. The controller allows 145-degree swivel movement and can be operated at the front or right side of the machine.

4. Bellows type roof-top cover ensures chip and coolant containment. The middle section can also be easily and automatically unlatched and moved back on a track by cylinder when loading heavy parts on the table with an overhead crane.

5. Easy operator access to the tool magazine for the quick change of tools.

More information, please contact:

HSM Machinery Co., Ltd.

6/155 Moo 7 Srinakarin Road, Bang Muang, Muang, Samutprakarn 10270

Tel : 02-7599445

Fax : 02-7599446

E-Mail: [email protected]

Website : www.hsm.co.th