New BALINIT MAYURA coating from Oerlikon Balzers enables maximum precision and productivity for machining and forming non-ferrous materials

New BALINIT MAYURA coating from Oerlikon Balzers enables maximum precision and productivity for machining and forming non-ferrous materials

Balzers, Liechtenstein, 13 September 2022 – Oerlikon Balzers, a global market-leading technology brand from Oerlikon for high-quality surface solutions, has launched BALINIT MAYURA, a new carbon-based coating for machining and forming non-ferrous materials. With BALINIT MAYURA, manufacturers and end users benefit from longer tool service life and higher productivity in the manufacturing process.

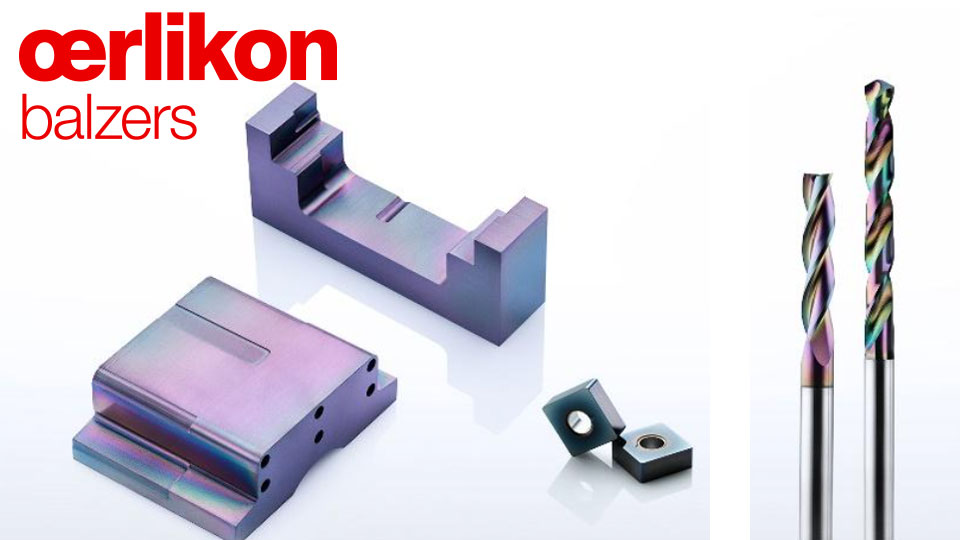

BALINIT MAYURA makes an immediate visual impression with its unmistakeable bright rainbow colours. But it shows its true value in the challenging process of demanding machining and forming of non-ferrous materials, such as aluminium alloys containing up to 12% silicon, copper alloys like phosphor bronze or brass and polymers.

Aluminium alloys are especially common in the automotive and aerospace industries, though they are also used in other sectors. Their low weight compared with conventional materials helps them play a major role in complying with the strict CO2 and NOx emissions requirements. And with the growing importance of e-mobility, processing copper alloys is becoming ever more vital. “BALINIT MAYURA is a solution tailored to meet these exact challenges for our customers’ materials, processes and applications, and it gives them optimum performance at lower manufacturing costs”, says Dr Andreas Reiter, Head of Product Line Tools at Oerlikon.

BALINIT MAYURA is harder and smoother than comparable coatings, as well as being extremely thin and heat-resistant. These properties make it especially suitable for the demanding processing of non-ferrous

materials. Its higher hardness and extraordinary smoothness effectively reduce material adhesion, which in turn minimises built-up edges and optimises chip flow. The minimal coefficient of friction due to its low roughness also enables lower torques, and when punching and forming aluminium, for example, the coating reduces the adhesion tendency and the formation of burrs and flakes.

The coating is extremely thin, which helps keep cutting edges sharp. That means manufacturers and end users benefit from high precision, longer tool service life and a more reliable manufacturing process overall. And the new carbon-based coating also helps conserve resources, as tools can be recoated with BALINIT MAYURA multiple times.

The beauty of precision:

BALINIT MAYURA doesn’t just stand out with its brilliant colours: the next-generation carbon-based coating offers real value in the form of longer tool service life and higher productivity when machining and forming non-ferrous metals and polymers.

The outstanding coating properties of BALINIT MAYURA keep cutting edges sharp for longer and minimise material adhesion, resulting in maximum precision and productivity.

You can find more information on the BALINIT MAYURA page on our website:

www.oerlikon.com/balzers/balinit-mayura

For further information please contact:

Petra Ammann

Head of Marketing Communications Balzers

T +423 388 7500

[email protected]

www.oerlikon.com/balzers

About Oerlikon

Oerlikon (SIX: OERL) is a global innovation powerhouse for surface engineering, polymer processing and additive manufacturing. The Group’s solutions and comprehensive services, together with its advanced materials, improve and maximise the performance, functionality, design and sustainability of its customers’ products and manufacturing processes in key industries. Having developed pioneering technology for decades, everything Oerlikon does is guided by its passion to help its customers achieve their goals and to foster a sustainable world. The Group is headquartered in Pfäffikon, Switzerland, and operates its business in two divisions: Surface Solutions and Polymer Processing Solutions. It has a global footprint of more than 11 800 employees at 207 locations in 38 countries. In 2021, Oerlikon generated CHF 2.6 billion in sales and invested CHF 105 million in R&D.

About the Balzers technology brand

Oerlikon Balzers is worldwide recognised for its leading surface technologies that significantly improve the performance and durability of precision components as well as tools for the metal and plastics processing industries. Extremely thin and exceptionally hard coatings, marketed under the BALINIT and BALIQ product names, reduce friction and wear. BALITHERM opens up a broad range of heat treatment services, whereas BALTONE comprises coatings that are available in a full range of elegant colours, perfectly suited for decorative applications. BALIMED ThinFilm coatings, with wear-resistant, biocompatible, antimicrobial and chemically inert properties, have been developed especially for medical applications. Under the BALIFOR product family, Oerlikon Balzers has introduced technologies which provide tailor-made solutions for the automotive market, while ePD allows the metallisation of plastic parts with a chrome look.