OKAMOTO Leads the Way with 'Automatic Grinding Machines' at METALEX 2023

Cutting-edge automatic grinding solutions from Okamoto make their debut at METALEX 2023, driving the transition towards an innovation-rich manufacturing era.

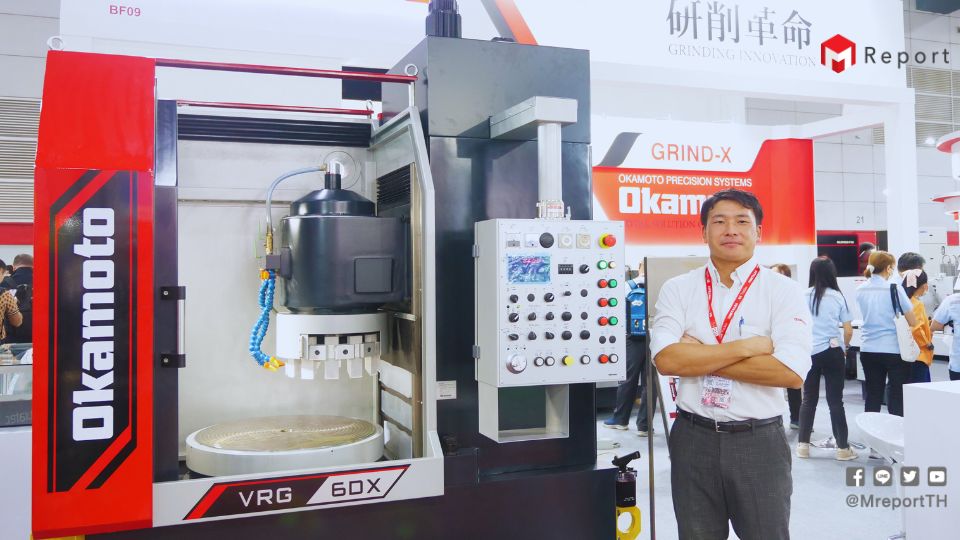

Okamoto (Thailand) Co., Ltd., the sole manufacturer and distributor of comprehensive abrasive process machines, showcases its advanced technology at METALEX 2023 from November 22-25 at BITEC, Bangkok. Explore Okamoto's technology at Hall 101 Booth BF09

Keita Nakayama, Sales Manager of Okamoto (Thailand) Co., Ltd., spoke to M Report about the machines and technologies featured in this event.

Okamoto emphasizes three benefits: “Cutting-edge, Fast and Simple, and Environmentally Friendly.”

Nakayama revealed that in past METALEX exhibitions, Okamoto mainly displayed the popular manual grinding machines. However, this time is different. The market trend demands cutting-edge technology that is cutting-edge, fast and simple, and environmentally friendly. Even though the global situation remains uncertain, this trend is unavoidable.

METALEX 2023 presents a great opportunity for Okamoto to introduce the “cutting-edge automatic grinding solutions” through two featured machines: the vertical grinding machine VRG-DX Series and the HPG500NC, accompanied by the Quick Touch measuring device.

Updating Okamoto's Cutting-Edge Automatic Grinding Solutions at METALEX 2023

Okamoto's cutting-edge automatic grinding solutions are presented through two technologies: VRG-DX Series and HPG500NC with Quick Touch. These technologies emphasize three benefits: "Cutting-edge, Fast, and Environmentally Friendly," driving the transition towards an innovation-rich manufacturing era.

1. Vertical Grinding Machine VRG-DX Series

The VRG-DX series gathers high-performance grinding concepts and delivers high productivity. Designed with a vertically rotating axis, this new innovation will revolutionize the grinding process, ensuring the best results, reducing NG, and excelling in precise grinding across a range of materials including Glass, Quartz, Sapphire, SiC, Die/Mold, Steel, Hydraulic & Pneumatic Parts, and Bearings.

2. HPG500NC with Quick Touch Measuring Device

The high-precision surface grinding machine HPG500NC elevates "accuracy" in setting vertical and horizontal positions, allowing even finer adjustments down to 0.1μm. Additionally, it eliminates the use of hydraulic oil, avoiding heat transfer and reducing energy consumption, making it even more environmentally friendly.

A special feature of the HPG500NC showcased in this event is the installation of the Quick Touch measuring device, a touch probe that enables immediate measurement of workpieces on the grinding machine, eliminating wasted time from setup and workpiece movement for measurement.

For those interested, you can catch up on the trend of "cutting-edge automatic grinding solutions from Okamoto" at Hall 101, Booth BF09 METALEX 2023, from November 22-25, 2023, at BITEC, Bangkok.

#Okamoto #Grinding #Technology #Mreport