Tungaloy Asia Seminar 2025: Inside Japan’s Cutting Tools Innovation and Green Technology

Discover Cutting Tools Innovation at Tungaloy’s Sustainable Japanese Factory

Building on the momentum of the Dealer Seminar 2025 hosted by Tungaloy-NTK Thailand, the journey continued in Iwaki, Japan—home to the Tungaloy Corporation headquarters. From July 14–18, Tungaloy Corporation welcomed over 100 customers from across Asia to the “Tungaloy Asia Seminar 2025,” featuring a comprehensive factory tour and an in-depth look at the company's advanced technologies, vision, and organizational culture that have made it a global leader in cutting tools.

From 95-Year Legacy to Global Innovation

The name Tungaloy stems from “Tungsten + Alloy,” tracing back to its founding in 1929, when Toshiba launched its cemented carbide business. Today, Tungaloy is part of the IMC Group under Warren Buffett’s Berkshire Hathaway, enabling the company to accelerate its technology development and product innovation at a global scale.

Full-Spectrum Production for Every Material and Technology

Tungaloy and NTK—both under IMC—form a seamless partnership offering tooling solutions for all materials including PVD, CVD, CBN, PCD, ceramics, and cermet. The Iwaki Plant, which includes 12 manufacturing buildings (with one more set to launch in October), serves as a centralized hub for R&D, production, and marketing. This structure gives Tungaloy an edge over Japanese competitors in speed-to-market and tailored product development.

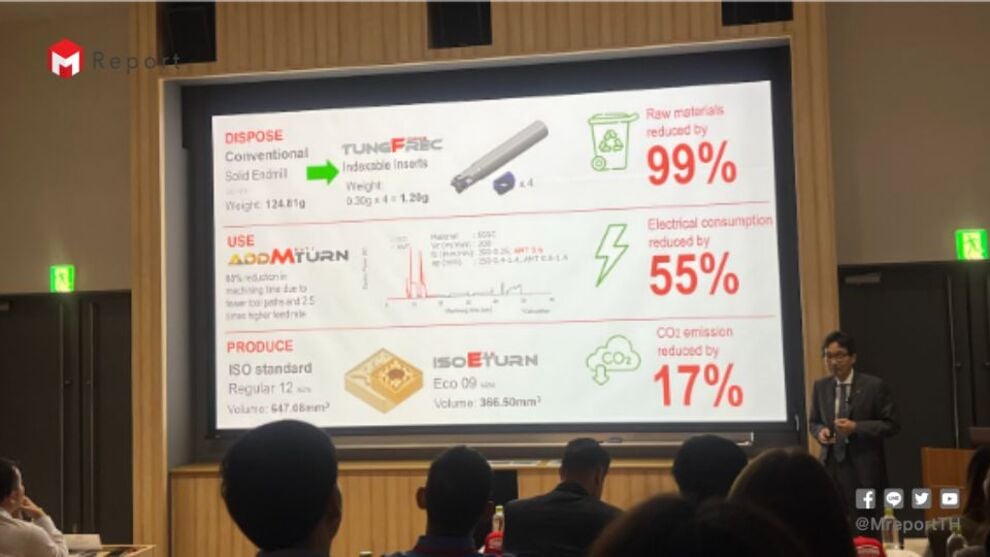

Supporting factories in Nagoya, Nirasaki, and Kyushu enhance capacity. In the last two years, the company has launched over 1,500 new items and filed more than 650 patents globally—anchored in its “3 Environmental Pillars: Dispose, Use, Produce.” Key examples include switching from solid endmills to TungForceRec (99% less raw material) and installing solar panels to reduce 82 tons of CO₂ annually.

Inside the Factory: Live View of World-Class Cutting Tool Production

A key highlight of the seminar was the live factory tour showcasing the complete process—from producing CBN blanks under ultra-high pressures of up to 6 GPa and 1,500°C temperatures to Additive Manufacturing (3D printing) used to produce next-generation tools like the ADDForceCut, which enables more efficient internal coolant systems, and the DrillMeister, which reduces production steps from five to just one.

Insert manufacturing—from pressing and sintering to grinding and PVD/CVD coating—was also featured. Each insert is laser-marked and tracked with traceability systems, underscoring Tungaloy’s commitment to high standards and quality control.

Driving Innovation for Modern Machining Challenges

Tungaloy is adapting to global industry demands with highly specialized solutions across sectors:

- Automotive: Machining sintered metal and aluminum alloys with low cutting force and universal-grade inserts.

- Medical: Cutting titanium alloys with long tool life.

- Aerospace & Oil & Gas: Handling superalloys and heat-resistant materials with speed and stability.

Globalization efforts began in 2008, with domestic sales once accounting for 70%. By 2023, overseas sales reached 70%, reflecting global growth through innovative and sustainable product development and localized partnerships.

In 2025, Tungaloy is launching new tools under the “ADDFORCE” concept, including:

- TungTurn-Jet: Dual-direction internal coolant system for superior chip control and reduced heat, achieving up to 50% cost reduction when used with MiniForce-Turn.

- DrillMeister / AddMeisterDrill: Replaceable head drills with models like DMF flat-bottom drills capable of 5xD depth without pilot holes.

- TungForceRec (New): V-Joint Geometry inserts enhance strength, reduce vibration, and extend tool life.

A standout is the T9215 CVD grade with TM chipbreaker, set for Q3 2025 launch. Designed for steel turning, it balances wear and chipping resistance, offering smooth chip evacuation—even at deep depths—thanks to its optimized cutting-edge geometry.

Attendees also received insert-shaped keychains to commemorate the seminar and preview the upcoming product release.

These innovations weren’t just talked about—they were proven in live cutting demos, demonstrating real-world results in cost reduction, productivity gains, and environmental efficiency.

A Warm Welcome with Cultural Touches

Beyond the factory tour, Tungaloy hosted a dinner reception to welcome Asian customers and dealers. Mr. Satoshi Kinoshita, President and CEO of Tungaloy Corporation, personally attended the event. The highlight of the evening was a Taiko drum performance, a powerful display of Japanese tradition that left a lasting impression and reflected the company’s commitment to building long-term relationships across Asia.