How to Invest in Machine Tools in 2019

The year 2018 was another year that the technology in automation of the industrial sector had been developed, such as industrial robots, artificial intelligence and many others, mainly brought about by the global labor shortage. Amid the Chinese-U.S. trade war, manufacturers around the world needed to keep an eye on Chinese sanctions by the United States, resulting in a recession in the machine tools market towards the end of the year. Many machine manufacturers, such as Mitsubishi Electric, decided to move their production bases from China while some are still growing in the Chinese market and accelerating their production capacity to support the market demand. In addition, an internal problem that many manufacturers were faced with was the extension of the delivery of machinery due to shortages of machine parts owing to the rapidly increasing demand which had been a huge challenge since the end of 2017.

At the same time, another growing machine tools market is the Indian market. The Japanese manufacturers see that current Indian market conditions are on a par with when the Chinese market grew exponentially. The Indian market has also been constantly receiving large orders of machine tools.

However, technology has continued to develop to a higher level in order to meet the consumer needs for products of higher quality.

One of the contributing factors to do so is materials technology that arises from the demand for electric vehicles (EV) with lighter weight. That is the main driving force for the demand for renewable materials that have the same or higher strength with lighter weight such as carbon fiber reinforced polymer (CFRP), high tensile steel, and ultra-high tensile steel; all of which are materials that meet the requirements of the automotive manufacturers as well as new materials that are invented all the time in other industries.

In addition to having high production costs, these new materials are also difficult to be molded or transformed, resulting in an increase in the number of research and development projects to reduce the cost of producing these materials. This will become the main trend in the development of machine tools for a long while.

Another factor is the need for IoT and AI, which results in the soaring demand for semiconductors and other electronic components.

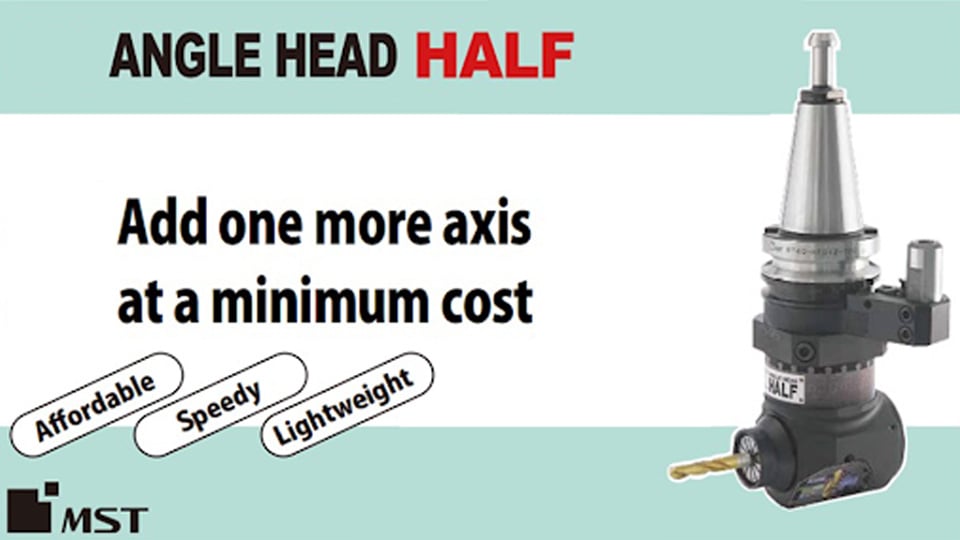

Both of these factors have made a number of machine tools manufacturers anticipate that the 5-axis machine will become a popular trend in the future since the production of parts made of new materials mentioned above can be difficult and high quality parts require higher work precision than ever before. The 5-axis machine that can firmly handle the workpiece and has a structure that facilitates the rotation of the workpiece and supports the end mill more efficiently can be the solution to all challenges.

Another trend is the machining center that is able to continuously function with high precision rates. It is becoming a current trend in presenting solutions to problems. Its flexibility meets the needs of the automotive industry for further development focusing on the use of parts together with platform. Its flexibility also meets the needs of other sectors, including being used in conjunction with injection molding machines, EDM machines, and robots and will be followed by creating additional value from after-sales services such as the remote monitoring.

In addition, last year many manufacturers viewed that IoT and AI were more than just "networking" as they could show concrete results. This has contributed to more widespread use of technology.

Coupled with the trend that many developers predicted that all machine tools will be able to thoroughly connect, effectively function automatically and be easily and remotely controlled, another upward trend is that the machine tools industry and the IT industry will be even more interrelated.