Die Technology Transforming Car Manufacturing for Quality and Sustainability

Innovative die technology is reshaping automotive manufacturing by ensuring precision, enhancing quality, and supporting sustainable, low-carbon production.

Data Collection of Skilled Craftsmanship

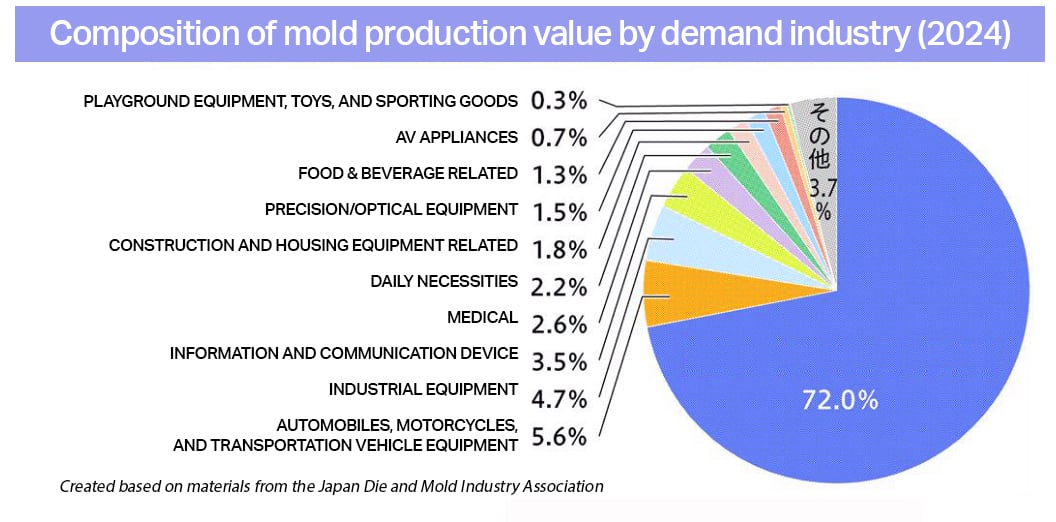

Auto parts manufacturers and mold makers are working to improve mold technology, which will lead to competitiveness in car manufacturing. The automotive industry is undergoing transformation in response to trends such as electrification and carbon neutrality (CN, essentially zero greenhouse gas emissions), and molds are evolving to support the production of highly designed parts, CN-compatible manufacturing processes, and digital transformation (DX). As Chinese mold makers emerge, Japanese companies need to pursue added value more than ever before.

| Advertisement | |

Auto parts manufacturers and mold makers are working to improve mold technology, which will lead to competitiveness in car manufacturing. The automotive industry is undergoing transformation in response to trends such as electrification and carbon neutrality (CN, essentially zero greenhouse gas emissions), and molds are evolving to support the production of highly designed parts, CN-compatible manufacturing processes, and digital transformation (DX). As Chinese mold makers emerge, Japanese companies need to pursue added value more than ever before.

Molds are the backbone of manufacturing. In the automotive industry, the trend toward CASE (Connected, Autonomous, Shared, and Electrification), lightweighting, and complex shapes is accelerating. This requires mold making with more advanced capabilities than ever before.

At the same time, the rise of price-competitive Chinese mold manufacturers has made it essential for domestic companies to differentiate themselves. The latest mold technology is no longer just a behind-the-scenes tool in parts manufacturing, but a key factor in production speed, cost reduction, and decarbonization.

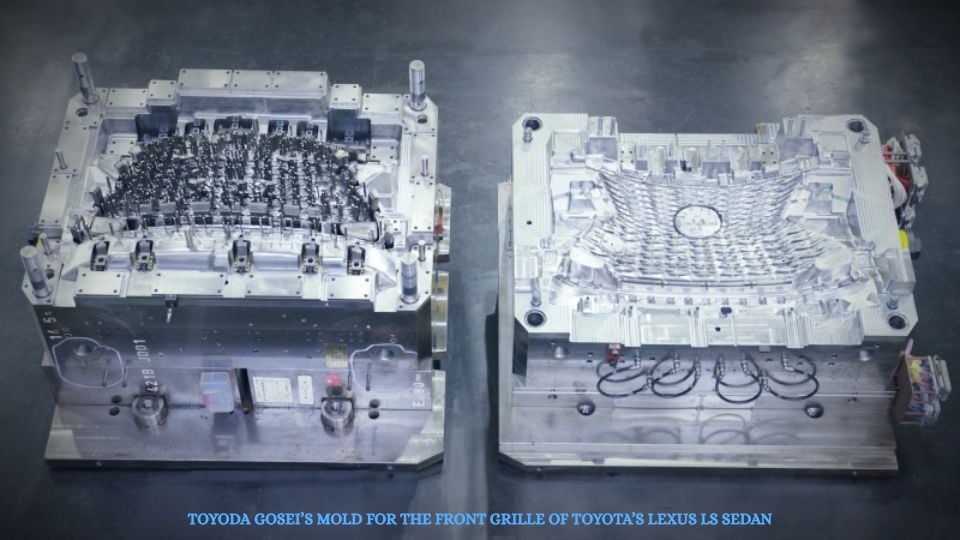

Toyoda Gosei has introduced a simultaneous 5-axis machining system to produce molds for components such as the front grille of Toyota’s Lexus LS sedan. As automotive designs have grown more sophisticated, the number of parts with complex geometries has increased, raising the level of difficulty in mold processing.

Traditionally, mold production relied heavily on the skills of master craftsmen. However, by digitizing this expertise, the majority of work can now be performed by advanced machining systems—reducing the burden on craftsmen and addressing labor shortages.

Unlike conventional 3-axis machining centers, which cut only along the X, Y, and Z axes, simultaneous 5-axis machining replicates the dexterity of a craftsman’s hand. It reduces the need for re-setup, eliminating misalignment, boosting efficiency, and enabling higher precision. This technology is also being applied to fine-detail molds, such as transparent emblems compatible with millimeter-wave radar used in preventive safety systems.

The initiative was led by Koji Yokoi, from TG’s Human Resources Development Center. When the study began in 2007, no domestic manufacturers produced simultaneous 5-axis machines, prompting Yokoi to travel to Germany to select a model. After extensive trial and error, he developed cutting conditions and tooling that could replicate the traditional Kan-Kotsu technique of master craftsmen. His work earned him the “Contemporary Master Craftsman” award from Japan’s Ministry of Health, Labour and Welfare in 2024. Yokoi has also focused on human resource development, raising overall technological levels in part design and manufacturing.

In-Mold Painting to Cut CO2

To meet growing demand for reduced CO2 emissions during production, Tokai Rika has started mass production of steering switches using in-mold painting technology, jointly developed with mold manufacturer Seiko Giken. This method integrates molding, painting, and drying within the injection molding machine itself, reducing CO2 emissions by 60% compared to traditional spray painting.

After injection molding, the rotary table turns, the mold top is switched, and special paint is injected and hardened using mold heat. This eliminates the need for large-scale intake, exhaust, and climate-control systems used in paint booths, further cutting energy use and equipment space requirements.

While metallic finishes remain a challenge, the current products already match the quality of conventional spray-painted parts. By 2030, Tokai Rika aims to expand the design range through micro-processing.

Smart Dies for Smarter Manufacturing

Technoa (Gifu City), in partnership with Tokai Rika and Gifu University, has developed pioneering press processing software that detects abnormal pressure during press operations and alerts the machine in real-time.

Thermal expansion of molds and press machines often causes abnormal pressure, leading to defects or damage. The software monitors pressure at a rate of 1,000 times per second, transmitting data wirelessly to adjust or halt machine operations.

This technology has been adopted in Tokai Rika Kaihatsu’s “Smart Mold”, enabling autonomous adjustment to dimensional changes caused by heat expansion. These smart molds are already being sold to companies engaged in press processing.

Steel for “Giga-Cast”

As automakers adopt “Giga-Cast”, a process for molding large body structural parts in one piece, demand for compatible molds is rising. These molds are far larger than conventional die-cast tools, requiring new solutions for durability, quality, and cycle times.

Daido Steel has launched “DHS-GIGA”, a mold steel specifically designed for Giga-Cast, already shipped to China for trial production. With chemical compositions adjusted to achieve four times the hardenability of standard hot-work steels, DHS-GIGA suppresses coarse bainite structures that reduce toughness.

In China, Daido will collaborate with Wuxi Dingfeng Rijin Metal Products (a Sumitomo Corporation Group member) for processing and supply. The company aims to expand sales globally, targeting annual revenues of ¥4 billion by FY2030.

Meanwhile, Shippo Mold Industry (Aichi Prefecture) partnered with Italian mold maker Costamp in November 2024 to expand sales channels and technical support for Giga-Cast molds. Anticipating rising domestic demand, Shippo is building Giga-Cast expertise while providing modification and repair services for Costamp molds.

Shippo specializes in die-casting mold design and manufacturing, with a strong record of business with major automakers in Japan and overseas. “We hope this partnership will lead to new orders from 2026 onward,” said Hirotaka Matsuoka, President of Shippo Mold Industry.